What are the current problems with the fully automatic paper mounting machine?

2020-03-20

Paper mounting machine manufacturer: The fully automatic paper mounting machine was introduced to the domestic market in 1995. At that time, due to the complexity of the new equipment structure, the complexity of the components, and the need to adjust many structural parts, the technical level of installation personnel, maintenance personnel, and operators was required, so the domestic market share was very low.

With the rapid development of the domestic packaging industry in the later stage, there are still technical problems in this area that have been addressed, and some new operational and technical problems have also emerged. Today, let's talk about these existing problems with everyone.

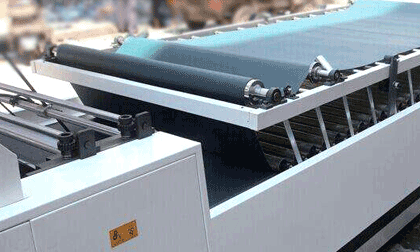

Introduction to the core part of the fully automatic paper mounting machine - paper feeding equipment

Some common problems with fully automatic paper mounting machines at present:

1. One of the factors affecting the speed of the large format is the low speed of the laminating machine, which uses a push gauge to transport the surface paper. When the speed is high, the impact of the push gauge on the surface paper will be significant, which can cause problems such as poor paper feeding and accumulation of surface paper.

2. The issue of lamination accuracy is that currently, the lamination accuracy of most machines is only 1.5mm, while foreign machines can achieve a high precision of 0.5mm; Moreover, there is already a significant gap between this precision and the precision requirements for printing. Even with the best printing effect, such paper mounting precision loses its original effect after being mounted in this way.

3. The phenomenon of delamination, flower sticking, weak adhesion, and translucency, as well as the influence of the amount of glue applied, will directly affect the quality of the lamination. If the amount of glue applied is insufficient, the adhesion will not be reliable. If the amount of glue applied is too large, there will be glue overflow, dirt, and translucency.

Paper mounting machine manufacturer: The above is all the content about the current problems of fully automatic paper mounting machines. If you have any questions, please feel free to consult website customer service!

Tag:

Recommended

The five components of the instant coating veneer machine