What are the common troubleshooting methods for paper mounting machines?

2020-03-04

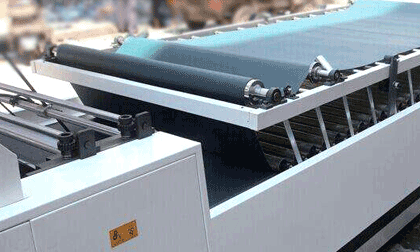

Common troubleshooting solutions for paper mounting machines: When semi-automatic paper mounting machines process lamination after printing, we may encounter the following problems? For example, how can we avoid wasting film mounting? What should I do if a dual-purpose paper mounting machine sometimes experiences wrinkling? Let's take a look at how to handle the common faults we encounter together?

(1) Be sure to wait for the imprint to dry thoroughly before using the laminating machine, otherwise it may cause product foaming or fuzzing.

(2) When mounting, we should pay attention to the direction of the paper threads, especially for thick paper, to reduce the phenomenon of paper curling caused by rolling and stretching.

(3) The product to be processed by the dual-purpose laminating machine after printing must be straight, and uneven paper with "ruffled edges" and "tight edges" should be treated first. The paper with "ruffled edges" can be baked, while the paper with "tight edges" can be hung and air dried.

(4) The temperature for post-press processing is generally controlled at 40-60 ℃. Excessive temperature can cause paper and film to deform, resulting in product curling. But it cannot be too low, otherwise it will cause insufficient viscosity.

(5) Try to spray less powder during printing, otherwise it may cause voids and bubbles in the powder pile. Before processing on the semi-automatic paper mounting machine, the powder should be sprayed off. For printing with a large quantity, it can be hung to remove the powder, while for printing with a small quantity, it can be manually wiped.

When the paper mounting machine operator is working, the following precautions should be taken:

(1) When checking the work handover book, the captain should pay attention to understanding the quality status of the production products, equipment, and the handling of abnormal situations. If the problems left over from the previous shift are not resolved, the captain needs to report to the supervisor for handling.

(2) Before production, the machine operator shall count the personnel of the machine. If any operator of the laminating machine is not present, the machine operator shall report to the supervisor for coordination and handling.

(3) Check if the tools are complete, if they are placed correctly, and if there are any debris on the machine. If the above situation occurs, immediately organize and clean it.

(4) Check the emergency switch and safety door safety device of the high-speed fully automatic paper mounting machine. When emergency switches and safety devices are found to be malfunctioning, stop production immediately, report to the supervisor and equipment department for maintenance, and keep records.

(5) Fill out a material and process defect feedback form for quality issues that frequently occur in the laminating process.

(6) Any abnormal situations that have not been fully handled by this class should be filled out in the work handover book and clearly handed over to the other class.

(7) Check whether the identification and quantity of semi-finished products in the process are accurate, whether there are any abnormalities in quality, and promptly report any problems to the captain and supervisor.

(8) Check if the material preparation for the planned production of the high-speed fully automatic paper mounting machine on duty is in place. If it is not in place, be responsible for following up on it.

Tag:

Recommended

The five components of the instant coating veneer machine