What are the common malfunctions of semi-automatic paper mounting machines?

2020-02-24

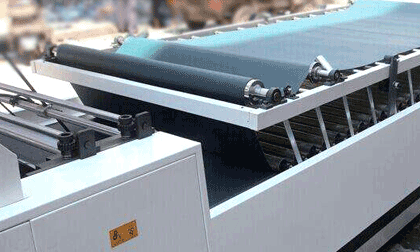

The semi-automatic paper mounting machine is now widely used in the printing industry, and it can be said to be an irreplaceable equipment for pre printed cardboard boxes, which has a huge impact on the entire production and sales process. Although the demand for usage is increasing, not everyone can use it correctly. Now let's take a look at the common problems that arise in the daily work of the paper mounting machine.

1、 Neglecting operational procedures

Many people believe that the operation of a dual-purpose laminating machine is quite simple, and it will turn on quite quickly when the instrument is turned on. In fact, when using it, the surface paper and corrugated cardboard should be arranged properly, otherwise it is easy to have positioning deviation and inaccurate surface pasting. This is the content that needs to be learned, so throughout the process, the corresponding positions should be adjusted and the uneven cardboard should be flattened.

2、 Adjustment error of semi-automatic paper mounting machine

To make good use of the dual-purpose laminating machine, it is necessary to adjust it correctly in daily life to avoid deviations. If there is any looseness in the delivery chain, it must be fixed as soon as possible to prevent instability or impact on one side. If the upper and lower rolling rollers are not cleaned and accumulate glue, it will also affect the transportation.

3、 Failure to properly maintain the semi-automatic paper mounting machine

If anything is not properly maintained, its production efficiency and quality cannot be maintained. Therefore, after buying the laminating machine, regardless of its accuracy or current work efficiency, relevant operators should be trained and regular cleaning work should be done to prevent damage.

What problems are common in the daily work of semi-automatic paper mounting machines? To make the printing and processing of cardboard boxes easier, it is important to take good care of such important equipment, which cannot be ignored.

Tag:

Recommended

The five components of the instant coating veneer machine