The five components of the instant coating veneer machine

2018-12-19

The instant coating veneer machine is a specialized equipment that applies adhesive to a roll of plastic film, dries it, and then combines it with printed materials through a pressurized composite part. The Xu type veneer machine mainly consists of five parts: unwinding, gluing and coating, drying, laminating, and winding

(1) Glue coating section

After unwinding, the film enters the gluing section through a coating roller. The coating forms include: drum reverse type, concave type, direct gluing without scraper, and direct gluing with scraper, etc

1) Concave gluing: composed of a metal gluing roller with a mesh engraved surface and a set of thin film partition rollers. The glue roller is directly immersed in the glue liquid, and the glue liquid is carried out from the glue storage tank with the rotation of the roller. The excess glue liquid on the surface of the roller is scraped off by a scraper. Under the action of the pressure film roller, the glue liquid in the groove of the roller is driven by the directionally moving film to be coated and evenly applied to the surface of the film.

2) Direct gluing with a scraper: The gluing roller is directly immersed in the glue and continuously rotates to drive the glue from the glue groove. After the excess glue is removed by the scraper, it contacts the surface of the film to complete the gluing.

3) Roller reverse glue coating: The glue roller takes out the glue from the storage tank, and the scraper roller and scraper can scrape the excess glue back into the storage tank. The film back pressure roller presses the film to be coated towards the surface of the evenly glued coating roller, maintaining a certain contact area. Under the action of pressure and adhesive force, the adhesive liquid is continuously applied to the surface of the film.

4) Squeezing glue coating without scraper roller: The glue coating roller is directly immersed in the glue liquid. During coating, the glue roller takes out the glue liquid, which is evenly mixed by the glue roller. The glue coating is completed by the extrusion pressure between the pressure film roller and the glue coating roller.

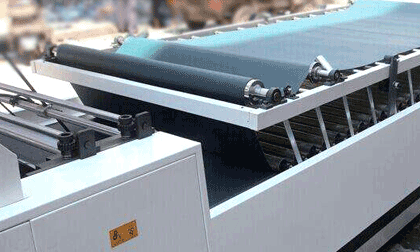

(2) Composite part

Mainly composed of chrome plated hot press rollers, rubber pressure rollers, and pressure adjustment machinery, etc

1) Hot press roller: It is a hollow roller with an electric heating device installed inside. The temperature of the roller is controlled through sensors and a control panel. The surface condition and thermal power density of the hot press roller have a significant impact on the surface quality.

2) Rubber pressure roller: Apply a certain pressure to the hot pressing roller to solidify and adhere the veneer product. Rubber pressure rollers are often exposed to high temperatures for a long time, while maintaining a flat and smooth roller surface with minimal lateral deformation, as well as good tear and peel resistance. Therefore, rubber with good tear resistance is often used.

3) Pressure adjustment mechanism: The pressure adjustment mechanism can use simple eccentric mechanism, screw, nut mechanism, etc., but in order to simplify the transmission components of the mechanism and improve the accuracy of pressure control, hydraulic adjustment mechanisms are currently mostly used.

(3) Unwinding section

The unwinding operation of plastic film requires the film to always maintain a constant tension. If the tension is too high, it is easy to produce longitudinal wrinkles, and vice versa, it is easy to produce transverse wrinkles, which are not conducive to the coating of adhesives and the composite with printed materials. To maintain appropriate tension, the unwinding section is generally equipped with tension control devices, commonly including mechanical friction disc clutches, AC short motors, magnetic powder clutches, etc.

(4) Dry section

The adhesive coating applied on the surface of plastic film contains a large amount of solvent and has a certain fluidity. Before composite, it must be dried. According to the solvent evaporation mechanism, the drying channel is designed into three zones

1) Evaporation zone: Turbulent air should be formed on the surface of the film as much as possible to facilitate solvent evaporation.

2) Maturation zone: An automatic temperature control zone is set based on the properties of the film and adhesive. The heating methods include infrared heating, direct radiation heating with electric heating tubes, etc. The automatic balance temperature control is achieved by thermal sensitive elements installed in the maturation zone.

3) Solvent Exclusion Zone: In order to timely eliminate the solvent emitted during the drying of the adhesive and reduce the vapor pressure in the drying channel, this zone is designed with an exhaust and extraction device, usually a fan or induced draft fan.

(5) Roll up section

Veneer machines often use automatic winding mechanisms, and the winding shaft can automatically wind the composite products into rolls. To ensure consistent tension during winding, the speed of the winding shaft and the composite line must be synchronized, and the tension during winding must be kept constant. As the winding diameter increases, its linear speed must continue to synchronize with the composite linear speed. Generally, machines use friction damping to change the angular velocity value of the winding shaft to meet the above requirements. To improve efficiency, some veneer machines are also equipped with fast unwinding and finished product slitting devices in the winding section.

Tag:

Recommended

The five components of the instant coating veneer machine