Eight preparations to be done before the production of the laminating machine

2018-11-13

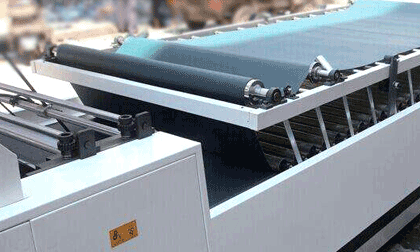

Before the daily production of the paper mounting machine, the following eight preparations should be made:

(1) The captain should correctly understand the requirements of the construction order before starting up, and check whether the samples and work orders are complete and consistent. If it is a product without samples or construction orders, production shall not be carried out and department supervisors shall be notified in a timely manner. When the requirements for the construction order of the paper mounting machine cannot be fully understood, it is necessary to inquire with the team leader and supervisor clearly, and production should not be based on subjective speculation.

(2) Check if the products to be mounted are properly prepared. If they are not in place, report to the team leader and assist them in handling the products. Check the preparation of the glue. The receipt of glue should be filled out on a material requisition form, which should be signed by the supervisor and collected from the warehouse. When receiving, the model of the glue should be clearly identified.

(3) Before starting work every day, it is necessary to refuel and lubricate the paper mounting machine. Be serious, comprehensive, and cannot miss anything. At the same time, observe whether there is any blockage in the oil hole. Once found, it should be removed and unblocked.

(4) Place the table paper and the base paper on separate paper racks, and adjust the width of the table paper and the base paper, ensuring that the paper is centered. When loading paper, pay attention to ensuring that the grain of the paper is perpendicular to the drum. The base paper should be based on the bite and pull gauge of the surface paper, and the position should be determined without exceeding.

(5) The adjustment of glue has a significant impact on the paper mounting machine, which generally depends on the water absorption of the paper. Paper with high water absorption requires more glue, while the opposite is true. If there is too much glue, it is easy to apply adhesive to the paper, but if there is too little glue, it will not bond firmly.

(6) Before starting the veneer machine, 20-30 pieces of waste paper should be selected for trial mounting. Check if the adhesion is firm, if the mounting paper is in place, and if there are any traces of glue. Production can only be carried out after the quality is stable and confirmed by the team leader and supervisor.

(7) Check if the electrical switches, brakes, and other components are flexible and reliable. If there are any abnormalities, they must be reported to the team leader or supervisor, promptly obtained from the maintenance department, and resolved as soon as possible.

(8) Pay attention to observe whether the laminating machine has any abnormal reactions. If there are abnormal noises, abnormal actions, or local overheating of the machine, it should be stopped immediately for inspection. If encountering unresolved problems with machinery and equipment, the team leader and supervisor should be notified, a repair form should be filled out, and the equipment department should be notified for maintenance. Attention should be paid to specifying the phenomenon and location of the machine malfunction.

Tag:

Recommended

The five components of the instant coating veneer machine