What are the structural characteristics of a paper mounting machine?

2020-03-09

The structural characteristics of paper machines are mainly reflected in the following aspects:

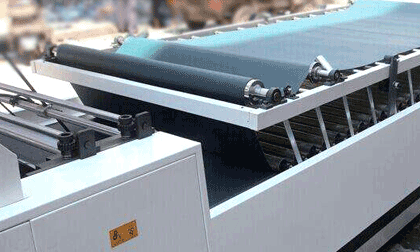

The paper mounting machine belongs to the field of paper making machinery, especially a fully automatic paper mounting machine used for pasting two sheets of paper together. It is composed of a paper feeding mechanism, a paper mounting mechanism, and a paper pressing mechanism.

Two air heads are parallel installed on the paper feeding mechanism, and a middle positioning mechanism is installed on the Baosteel paper mounting machine. The paper mounting mechanism is divided into two paper paths, and wing shaped spring plates are installed on both sides of the semi-automatic paper mounting machine. The middle positioning mechanism is composed of a middle positioning guide block and an lifting unit.

This utility model has a simple structure, improves production efficiency, and adapts to the requirements of different sizes of paper. It is a fully automatic paper mounting machine that has no limit on the size of paper and can convert single or double sheet feeding. ▲

Another type of Baosteel laminating machine is composed of a paper feeding mechanism, a semi-automatic laminating machine, and a paper pressing machine. The paper feeding mechanism is composed of an upper and lower layer mechanism, while the paper mounting mechanism is composed of an upper and lower layer mechanism. Its feature is that two air heads are arranged side by side on the upper layer mechanism of the paper feeding mechanism.

There is a middle positioning mechanism installed on the paper mounting mechanism, which is divided into two paper paths. Wing shaped spring plates are set on both sides of the paper mounting mechanism. The middle positioning mechanism is composed of a middle positioning guide block and a lifting mechanism, which is connected to the lifting mechanism.

Solution to the problem of inaccurate mounting on the paper mounting machine

When using the laminating machine, if you encounter inaccurate lamination and after careful inspection of the two aspects we previously introduced, you still cannot find a solution, you can refer to our instructions today to make adjustments.

Before proceeding with the mounting process, we should carefully observe the appearance quality of the corrugated cardboard? Is there any roughness or breakage on the edges of the corrugated cardboard? Is there any flattening, collapse, or warping deformation of the cardboard? If the corrugated cardboard we produce has such problems, we should immediately conduct relevant tests to prevent further losses.

Another point we often mention is the issue of moisture. If the moisture content of corrugated cardboard is different and the machine operation is improper, it is easy to cause serious warping. After laminating the surface paper and core paper, it is also easy to cause inaccurate lamination due to relative slip during the rolling process.

Tag:

Recommended

The five components of the instant coating veneer machine