Introduction to the Adhesive Quality and Adhesion Degree of the Paper Mounter

2020-03-13

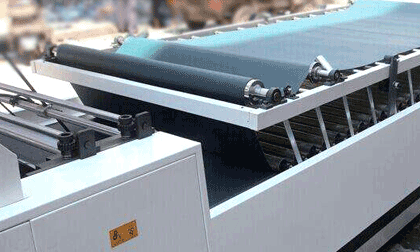

The laminating quality of the laminating machine refers to the maximum range of relative distance between the side paper and the edge of the base paper (i.e. corrugated paper or cardboard) after laminating with the surface paper (i.e. colored paper) according to the specified rules. Its value is generally ± 1, and the factors that affect this value can be divided into two parts: the first is the mechanical part, and the second is human factors.

The bonding principles of various manufacturers of the laminating machine can basically meet this requirement, but the requirements for the proficiency and skills of the operators (i.e., the strength or weakness of operability) are still high because semi-automatic laminating machines are still widely used in the market. So human factors play a decisive role. Therefore, the requirements vary slightly depending on the model.

The bonding quality of the laminating machine

It refers to the most prominent impact resistance and adhesion of finished cardboard. Both of these indicators are directly related to the adhesive, based on the use of unique adhesive powder.

Adhesion of paper mounting machine

The bonding strength between the base paper and the surface paper is the best bonding product, where the base paper and the surface paper are immersed in a mixture. If the immersion degree is too deep, it will cause corrugation, and if it is too shallow, it will cause incomplete bonding (i.e. explosion). If it is too shallow, it will open the adhesive. This requires evenly spreading the adhesive on the corrugated paper of the semi-automatic paper mounting machine, and ensuring sufficient immersion depth of the surface paper.

Here is a simple verification method:

1. Evenly apply the glue on the edge of the corrugated paper, which is more than one-third of the height of the corrugated paper. Make sure to scratch the coated surface of the corrugated paper with your hand to have a clear feeling of touching the glue;

2. The corrugated paper is bonded to the surface paper, and after applying pressure, before conveying and pressing, the semi-finished product is taken out. The surface paper is lifted and the adhesive marks on the surface paper are carefully observed. When the pressure of each conveying roller is suitable, this adhesive mark should be a continuous adhesive column line. When it is large, this adhesive mark is a adhesive mark with a certain width. When it is too large, there will be two adhesive marks with a smaller width. When it is small, this adhesive mark is a discontinuous adhesive column line.

Tag:

Recommended

The five components of the instant coating veneer machine