The difference between fully automatic paper mounting machine and semi-automatic paper mounting machine

2020-03-25

Paper mounting machine manufacturer: The paper mounting machine belongs to the category of paper manufacturing machinery, especially a paper mounting machine used to paste two sheets of paper together. It is composed of a paper feeding organization, a paper mounting organization, and a paper pressing organization. Two air heads are set parallel to the paper feeding organization, and a central positioning organization is set on the paper mounting organization. The paper mounting organization is divided into two paper paths, and wing shaped spring plates are set on both sides of the paper mounting organization, The central positioning organization is composed of a central positioning guide block and a lifting organization.

There are two common types of paper mounting machines: fully automatic paper mounting machines and semi-automatic paper mounting machines:

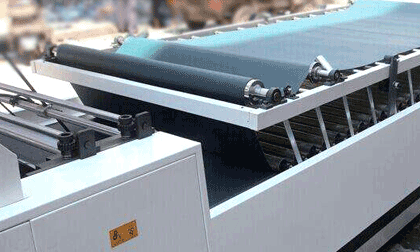

Fully automatic laminating machine: suitable for laminating color printing face paper and corrugated paper, using a combination of feeding face paper and wind driven bottom paper equipment to fully achieve automation.

The main features of the fully automatic paper mounting machine are:

1. Paper mounting machine manufacturer: Vacuum suction cup feeding system, which can accurately feed paper into the machine; The circular paper stacking rack can stack the next batch of face paper without stopping the machine, making efficiency higher;

2. The bottom paper is selected for suction active paper feeding, which can continuously and actively follow according to the operating speed of the host;

3. New concept pre positioning with high positioning accuracy, never leading the way with the base paper; The advance amount of the face paper is adjustable;

The entire machine adopts a touch screen/PLC control system, with stable circuit operation and the ability to actively display fault alarms;

4. The fully automatic glue replenishment system can actively replenish the lost amount of glue during the bonding process and cooperate with glue recycling to prevent glue loss and waste;

5. Scientific design of measuring roller linear speed to ensure uniform glue application and prevent glue throwing during high-speed operation;

6. Using a rubber roller for cleaning, the lower roller is completely clean, and the back of the corrugated paper is not sticky, saving the trouble of frequently replacing the scraper; Floating movable press ensures that the corrugated paper will not be flattened after lamination.

Ensure the flatness and straightness of the cardboard;

7. Using the single-sided adjustment method of worm gear and worm gear to adjust the pressure of the pressing roller, which is convenient and fast;

8. The cleaning water source adopts an independent water tank to control the water circulation method, which is clean and not easy to accumulate glue;

9. Suitable for laminating 175g-500g color printing paper with A/B/C/D/E/F corrugated paper.

The main characteristics of a semi-automatic paper mounting machine are:

1. The fitting accuracy is high, and it can basically reach the same straight line. It is not very important for operators, and even laypeople can operate proficiently through guidance. It is easy to install, has a reasonable structure, and is easy to operate. It is suitable for use in large, medium, small, and various printing and packaging enterprises.

2. It has multiple laminating functions and can be used to mount various types of thin and thick face papers. The requirements for the base paper are not high, and corrugated cardboard, cardboard, and multi-layer gray board paper can all be laminated. And after being mounted and pressed, there is no need to dry it, it only needs to be left for a few to ten minutes to be used.

3. The requirements for glue agents are not high, and both yellow glue and white glue can be used. And the glue is evenly applied, with a small amount of glue used, and the thickness of the glue layer can be freely adjusted, absolutely ensuring that every part of the entire paper has the same uniform glue. Equipped with active or manual glue extraction equipment, it is convenient and sensitive to use.

4. Equipped with chain transmission equipment, it has low noise, stable operation, and convenient use.

5. Compared with manual laminating machines, it has higher efficiency and faster speed.

6. The lamination quality is good, without sticking flowers, bubbles, scratches, and scratches, and the product has good stiffness.

7. The number of personnel required to participate in the homework is low, which reduces labor costs.

8. The press bed is equipped with unique paper feeding equipment, pressure regulator, and safety protection equipment, making equipment operations more efficient.

Tag:

Recommended

The five components of the instant coating veneer machine