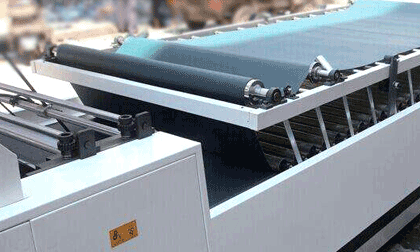

Paper mounting machine: Specific analysis of the main aspects when selecting a paper mounting machine

2022-07-22

Baoshun Equipment Reminder: Main aspects of selecting a laminating machine

1. Brand.

Generally speaking, choosing a brand is choosing a manufacturer, choosing large factories with large production scale and strong technical strength, because the performance and quality of the laminating machines they produce are relatively stable and reliable, and the after-sales service is also relatively guaranteed, which can withstand the test of time and use.

2. Model

There are three types of laminating machines according to the model: fully manual operation and simple structure, semi-automatic and fully automatic. The structure, performance, and price of laminating machines are also completely different for different models. The choice of the type of laminating machine for production mainly depends on the structure and characteristics of the factory's products. Reasonably arranging suitable machines for production is beneficial for improving production efficiency and quality.

3. Specifications.

The specifications of the laminating machine are relative to the length of the roller. In order to avoid waste of adhesive, energy consumption, and increased production costs, in factories with diverse product structures, different sizes of laminating machines should be selected proportionally when selecting specifications to meet production requirements.

4. Price.

Price is one of the important factors determining production costs and an important part of factory procurement. Due to differences in production capacity, scale, and management mode among different factories, their prices also vary. Therefore, when selecting prices, it is necessary to compare prices with other suppliers and also visit the market and customers to have a more accurate and clear understanding of the printing equipment market, ensuring the purchase of a paper mounting machine with appropriate prices and reliable performance.

5. Practicality.

The purchased laminating machine should meet production requirements in order to improve production efficiency and quality, and reduce production costs. Factories should determine their intention to purchase machines based on the characteristics of their product structure. For small batches and specifications, it is advisable to purchase manual paper mounting machines for mounting. For large quantities, hard materials, and products with high quality requirements, semi-automatic and fully automatic paper mounting machines should be selected for mounting. It is important to avoid purchasing fully automatic paper mounting machines for long-term mounting of small batches, small specifications, and uneven paper box products.

Dongguang County Baoshun Paper Box Equipment Manufacturing Co., Ltd. specializes in manufacturing paper box machinery such as laminating machines and veneer machines. Our main products include semi-automatic laminating machines, dual-purpose laminating machines, Baosteel veneer machines, fully automatic laminating machines, semi-automatic veneer machines, Baosteel veneer machines, high-speed fully automatic laminating machines, Baoshun veneer machines, veneer machines, fully automatic veneer machines, and other equipment. Welcome to consult and cooperate!

Tag:

Recommended

The five components of the instant coating veneer machine