Introduction to the structure and performance of semi-automatic veneer machine

2020-02-28

There are various structures of semi-automatic veneer machines on the market now, including ordinary veneer machines that rely entirely on manual operation, have simple structures, are inexpensive, occupy small machine space, have low production efficiency, slow glue drying, and can be produced by small mechanical factories.

This machine requires at least three people to operate. First, one person places the corrugated cardboard between the glue wheel and the rolling wheel, and then two people on the corresponding side jointly lift the surface paper and align it with the corrugated cardboard for lamination. This process is generally suitable for small batch, low-quality pre printed cardboard boxes.

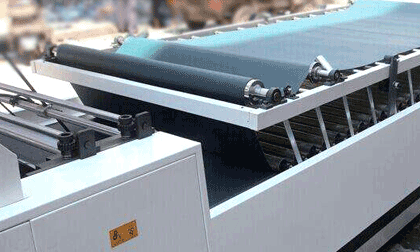

A semi-automatic veneer machine is a machine where two people simultaneously transport corrugated cardboard and tissue paper to a positioning system, which is then rolled and transported to a conveyor belt. Under the pressure of the conveyor belt, it achieves uniform lamination and has the characteristics of strong adhesion, less prone to foaming and delamination. The speed of the machine can be adjusted. However, due to the limitations of manual paper placement, high-speed lamination production will not be achieved.

The face paper and corrugated cardboard of the fully automatic veneer machine are both fed and transported automatically by vacuum adsorption. The conveyor belt and pressure belt at the rear are similar to semi-automatic machines. Due to the fast speed of the machine, the adhesive should be of the quick drying type. This machine has the advantages of high production efficiency and good lamination quality, making it more suitable for the production of hard and high-end pre printed cardboard boxes.

The adhesive formula used in semi-automatic veneer machines

Several characteristics of adhesive used in veneer machines and how to determine their advantages and disadvantages. Today, we will introduce a small formula of adhesive used in Baosteel veneer machines for your reference.

Firstly, prepare: 250kg of water; 50kg of starch; Hydrogen peroxide 2.5kg; 5kg of caustic soda; Sodium thiosulfate 0.75kg; Borax 2.5kg; There is also an appropriate amount of defoamer.

After preparing these materials, we add clean water to the iron can and pour in starch. After turning on the machine and stirring until the starch is completely hydrolyzed, we add hydrogen peroxide and caustic soda solution in sequence. After the reaction is completed, a yellow liquid is added and sodium thiosulfate is stirred evenly. Then, we add borax that has been hydrated with boiling water and continue stirring for 10 minutes.

Add defoamer at the tail and use it after the foam has receded. During the production process, special attention should be paid to controlling the viscosity of the adhesive between 25s and 30s. Otherwise, the Baosteel veneer machine will either shake the adhesive or have poor adhesion during operation.

I hope it can help you reduce costs and produce high-quality products in the adhesive field!

Tag:

Recommended

The five components of the instant coating veneer machine