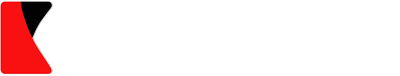

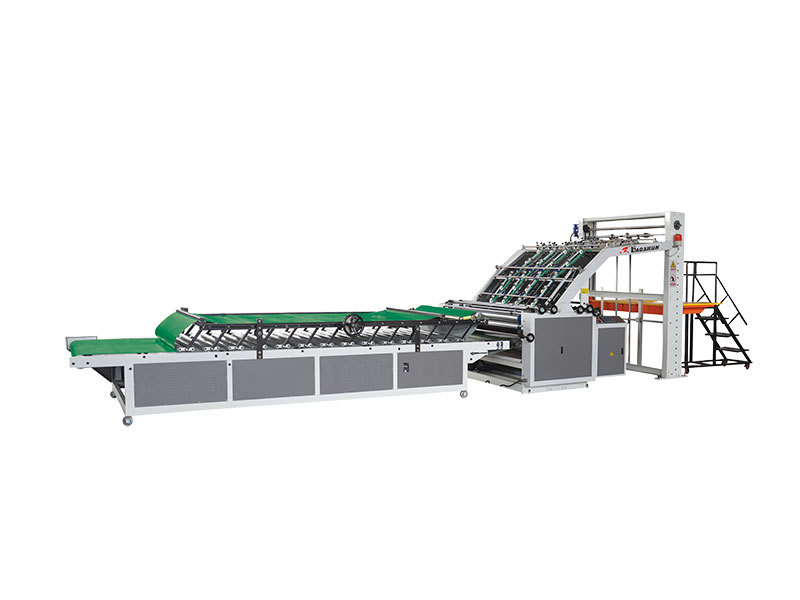

Corrugated production line

This production line is a specialized equipment for corrugated cardboard production. It mainly includes a paper stand, single facer, conveyor bridge, gluer, double facer, slitter scorer, cut-off machine, stacker, steam (or oil) heating system, and glue preparation and supply system. We provide advanced, medium, and simple level corrugated production lines, suitable for single-wall, double-wall, and triple-wall board production, with speeds ranging from 40 meters/minute to 200 meters/minute. Widths range from 1400mm to 2500mm.

Tag:

hiddenValue

- Product Description

-

This production line is a specialized equipment for corrugated cardboard production. It mainly includes a paper stand, single facer, conveyor bridge, gluer, double facer, slitter scorer, cut-off machine, stacker, steam (or oil) heating system, and glue preparation and supply system. We provide advanced, medium, and simple level corrugated production lines, suitable for single-wall, double-wall, and triple-wall board production, with speeds ranging from 40 meters/minute to 200 meters/minute. Widths range from 1400mm to 2500mm.

I. Overview

This production line is a specialized equipment for corrugated board production. It mainly includes paper stand, single facer, conveying bridge, gluing machine, double facer, slitter scorer, cut-off machine, stacker, steam (or oil) heating system, and glue preparation and supply system. We offer advanced, medium, and simple level corrugated production lines, suitable for single wall, double wall, and triple wall board production, with speeds ranging from 40m/min to 200m/min. Widths range from 1400mm to 2500mm

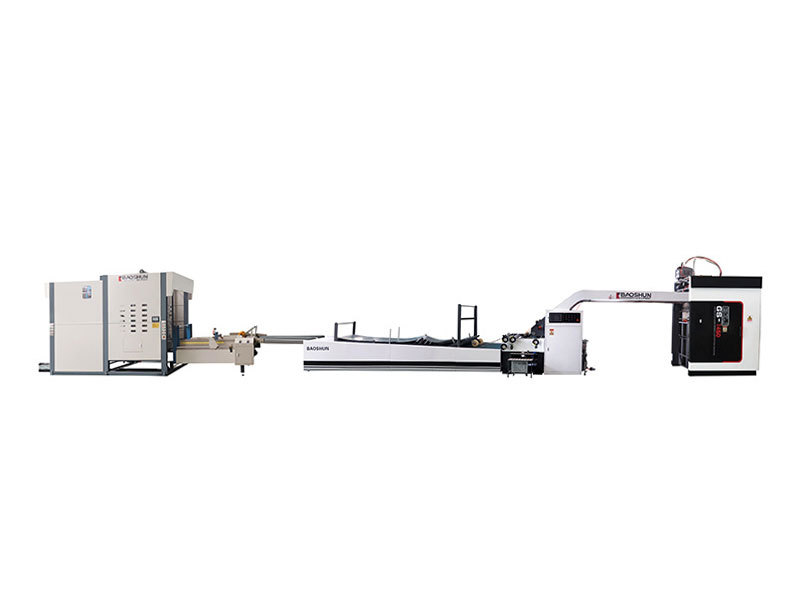

II. Line Composition

Design speed: 120m/min. Economic speed: 3-ply board 100m/min, 5-ply board 80m/min

No.

Name

Size

Configuration

Quantity

1 ES-B Electric Mill Roll Stand Φ1400mm Welded model, with expanding chuck and pneumatic brake 5 Rollers and trolley Standard 10 2 SF-DW105 Single Facer Φ280mm Alloy steel corrugating roll, frequency converter motor, electric adjustment of gluing width 2 3 TO Double Layer Overhead Conveyor Adsorption type and deviation electrically corrected 1 4 PH-B Single Roll Preheater Φ600mm Wrap angle electrically adjustable 4 5 PH-B Three-Roll Preheater Φ600mm Wrap angle electrically adjustable 1 6 PM-C Double-Roll Gluing Machine Φ210mm With shaft load 1 7 DF-C Double Facer 30-inch standard channel and hot plates 600mm*12 pieces With strong pressure rollers, hydraulic lifting of pressure shaft, 2 cotton belts, universal joint drive, cooling section: 4m 1 8 Electric Online Slitter Scorer 1400mm model 4 blades 6 scorers, electric blades, manual scorers 1 9 SC-B Straight Knife Cut-off Φ188mm Standard 1 10 RF-A Square Output Machine Standard 1 11 Glue Making System Standard 1 12 Air Source System Steam Tank 0.6m³ Standard 1 Air Storage System With pressure gauge and gas-water separator III. FAQ

1. Q. Are you a trader or a manufacturer?

A. We are a manufacturer with export qualifications.

2. Q. Do you do OEM?

A. Yes, we can.

3. Q. Where is your factory located?

A. We are in Dongguang Town, Cangzhou City, Hebei Province, China.

4. Q. Where is the nearest airport to the factory?

A. The nearest airports are in Tianjin, Jinan, and Beijing. It takes 4 hours to drive from Beijing to Dongguang.

5. Q. Where is the nearest high-speed train station? How long does it take from the high-speed train to the factory?

A. The nearest station is Cangzhou West Station, it takes 1 hour from Beijing to Cangzhou.

6. Q. What is your business process?

A. Discuss customer requirements, confirm machine, sign sales contract, pay deposit, supplier arranges production, complete machine production, buyer tests machine, buyer pays final balance, supplier loads and ships machine.

7. Q. How do you control machine quality?

A. 1. Our company has a strict quality control system from production to delivery since its establishment 23 years ago.

2. We focus on reducing energy consumption and low pollution.

3. We have professional technicians to supervise production.

4. There is a professional department to inspect each production process.

8. Q. Can engineers go abroad to debug machines?

A. Our engineers can go abroad to debug machines, but the buyer needs to bear the engineer's round-trip airfare, food and accommodation, and a salary of $100/day.

Product Consulting