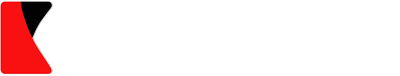

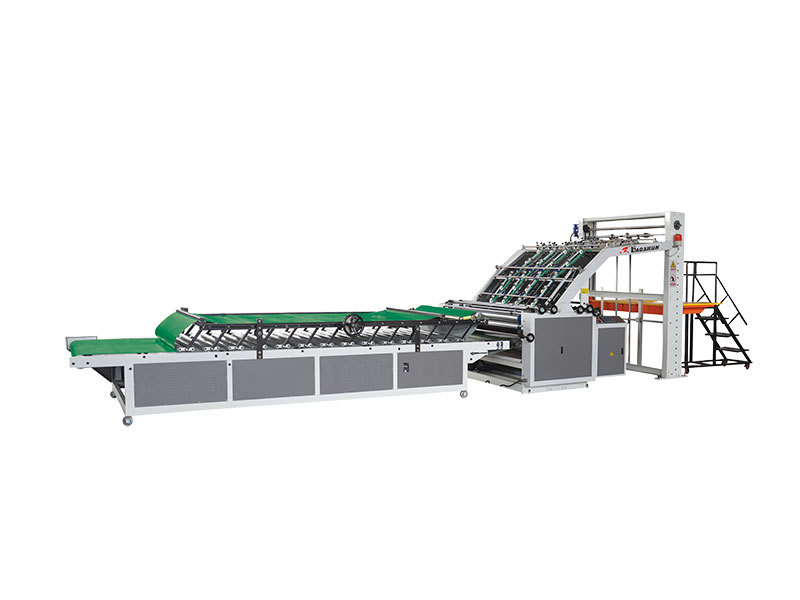

DX-2000 Single-Piece Dual Servo Carton Stitcher

The dual-servo high-speed semi-automatic stitching machine is a specialized equipment for the final forming process of corrugated cardboard boxes. Through technological updates, this machine achieves high production efficiency, fast stitching speed, low labor intensity, simple operation, stable performance, reliable operation, and a low failure rate. The dual-servo high-speed semi-automatic stitching machine is primarily used for stitching single-piece corrugated cardboard forming to meet the requirements of multi-variety and different batch production, adapting to the needs of various domestic sales and export product carton packaging. It is a replacement for manual stitching machines and is currently the latest and most ideal semi-automatic carton equipment in China.

Tag:

hiddenValue

- Product Description

-

The dual-servo high-speed semi-automatic stitching machine is a specialized equipment for the final forming process of corrugated cardboard boxes. Through technological updates, this machine achieves high production efficiency, fast stitching speed, low labor intensity, simple operation, stable performance, reliable operation, and a low failure rate. The dual-servo high-speed semi-automatic stitching machine is primarily used for stitching single-piece corrugated cardboard forming to meet the requirements of multi-variety and different batch production, adapting to the needs of various domestic sales and export product carton packaging. It is a replacement for manual stitching machines and is currently the latest and most ideal semi-automatic carton equipment in China.

Machine technical parameters:

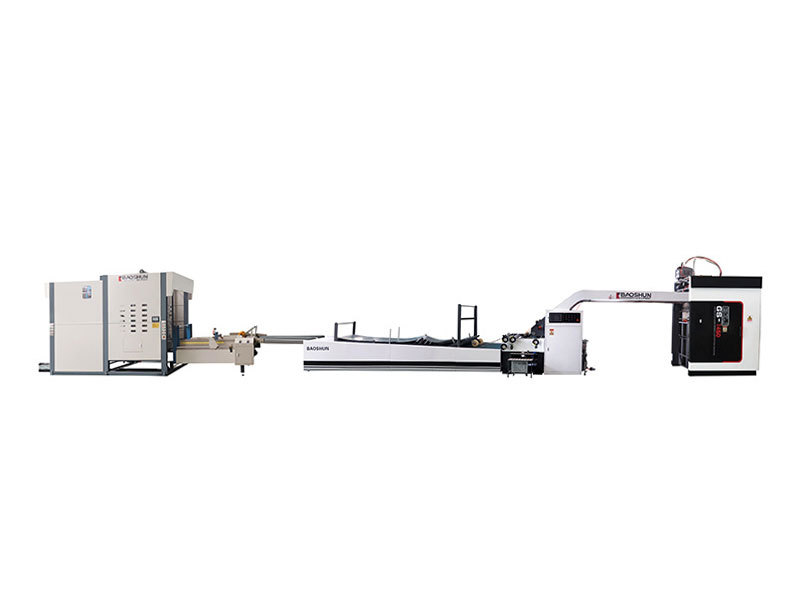

SDX-3500 Four-servo Semi-automatic Double Stitching Machine List

Model and Parameters

SDX-2500

SDX-3000

SDX-3500

SDX-4000

Max. paper size

4000 4800 6000 7000 Min. paper size

1060 1060 1060 1060 Max. carton length

1850 2350 2850 3350 Min. carton length

350 350 350 350 Max. carton width

1000 1200 1500 1800 Max. paper height

2500 2500 2500 2500 Min. paper height

400 400 400 400 Max. flap size

560 560 560 560 Min. flap size

50 50 50 50 Max. height

2000 2000 2000 2000 Min. height

150 150 150 150 Max. stitching tab width (mm)

45 45 45 45 Stitching distance (mm)

30-120 30-120 30-120 30-120 Number of stitches

1-99 1-99 1-99 1-99 Stitching speed (stitches/minute)

500 500 500 500 Machine weight (tons)

2.5 3 3.5 5 Power

7 kW 7 kW 7 kW 7 kW Total: FOB Tianjin Port, China (USD) Note: (Installation fees are not included in this price)

1. Quotation date: Validity: 30 days

2. Delivery: 30-50 days after receipt of deposit

3. Payment method: 30% down payment by T/T, 70% by T/T before shipment

4. Installation and training: The buyer needs to pay for round-trip air tickets, accommodation, and daily wages of 100 USD per engineer)

5. Warranty period: 12 monthsMain functions

The dual-servo high-speed semi-automatic box stitching machine is a specialized equipment for the final formation of corrugated cartons. Through technical updates, this machine has the advantages of high production efficiency, fast stitching speed, low labor intensity, simple operation, stable performance, reliable operation, and low failure rate. The dual-servo high-speed semi-automatic box stitching machine is mainly used for the stitching of single-piece corrugated board forming to meet the requirements of multi-variety, different batch production, and adapt to the needs of various domestic and export product carton packaging. It is a substitute for manual box stitching machines and is currently the latest and most ideal semi-automatic carton equipment in China.

Component functions

Adopts Japan Yaskawa servo drive control system and Weintek touch screen.

Can perform single-stitch, double-stitch. Reinforced stitches can be completed in one go, meeting the stitching requirements of different customers.

Quick size change in one minute, easy operation, no experience required.

Automatic counting in the feeding section, bundled and then sent out for strapping.

Automatic counting in the rear section; finished products can be stacked and sent to the end of the conveyor belt according to the set quantity (1-99) (convenient for strapping).

Human-machine interface control, convenient operation.

Maximum stitching distance can reach 160 mm

Stitching distance can be set directly on the touch screen.

Electric adjustment of rear baffle, order storage function.

Fastest stitching speed: 600 stitches/minute

Only two operators are needed from semi-finished product stitching to finished product placement, which is simple and convenient to operate, reducing labor costs.

DX-2000 Type Servo High-speed Semi-automatic Carton Stitching Machine Configuration List

Serial No. Name Brand Origin Note 01 Stitching head servo motor Yaskawa Japan 1 unit 02 Feeding servo motor Yaskawa Japan 1 unit 03 PLC Delta Taiwan 1 piece 04 Contactor Siemens Germany 05 Intermediate relay Schneider France 06 Cylinder and pneumatic components YIRI China 07 Solenoid valve AIRTAC Taiwan 2 pieces 08 Touch screen 3/5000 Weintek Taiwan 1 piece 09 Stitching head assembly China 1 set 10 Blade bottom die German alloy steel 1 set 11 Zeroing switch Omron Japan 12 Photoelectric switch Omron Japan 13 Gear reduction motor Taibang Taiwan 3 units 14 Worm gear reducer Renmin China 2 units 15 Brake Motor Oute China 1 unit 16 Bearing Renben China

Product Consulting