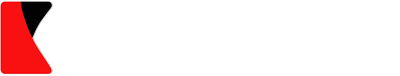

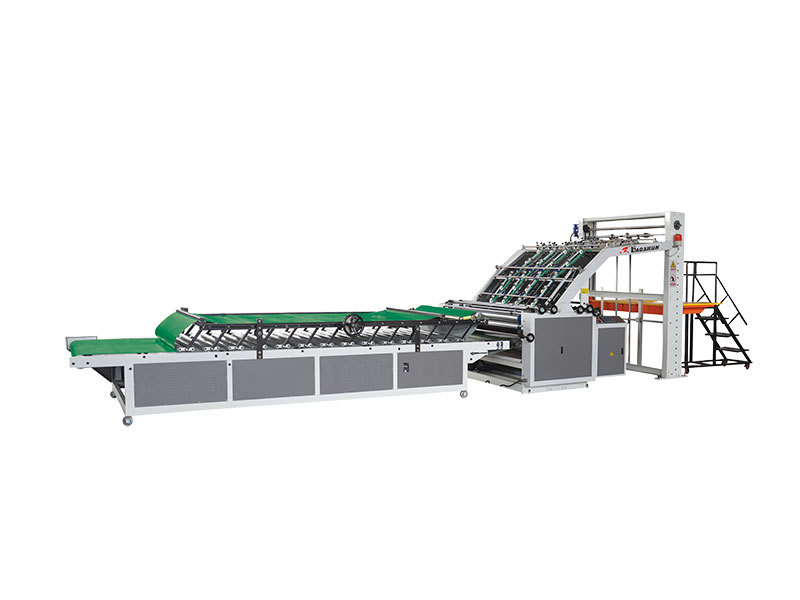

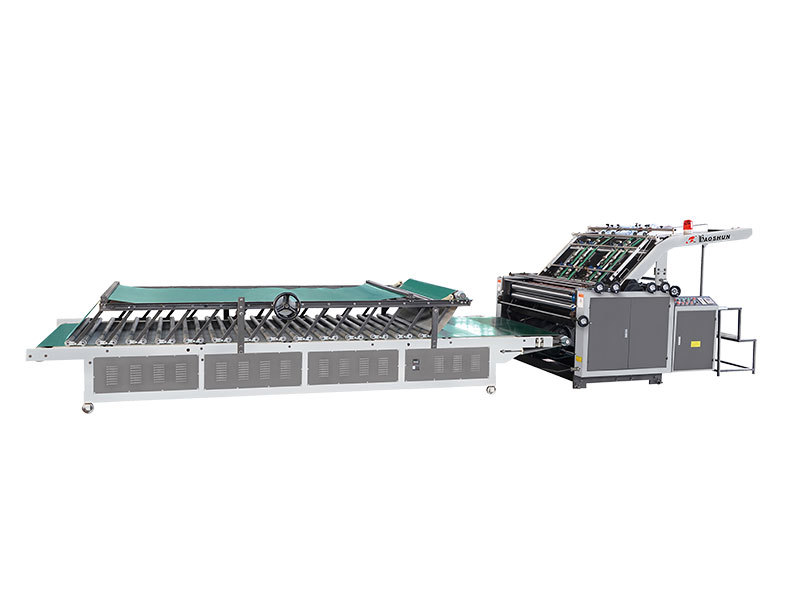

SDX-2500 Four-Servo Double-Piece Semi-Automatic Carton Stapler

German Siemens/Japanese Mitsubishi original imported dual servo drive, accurate precision, reduced mechanical transmission parts, can effectively reduce the mechanical failure rate.

Tag:

hiddenValue

- Product Description

-

German Siemens/Japanese Mitsubishi original imported dual servo drive, accurate precision, reduced mechanical transmission parts, can effectively reduce the mechanical failure rate.

Machine technical parameters:

SDX-3500 Four-Servo Semi-Automatic Double Stitching Machine List

Model and parameters

SDX-2500

SDX-3000

SDX-3500

SDX-4000

Max paper size

4000

4800

6000

7000

Min paper size

1060

1060

1060

1060

Max carton length

1850

2350

2850

3350

Min carton length

350

350

350

350

Max carton width

1000

1200

1500

1800

Min carton width

180

180

180

180

Max paper height

2500

2500

2500

2500

Min paper height

400

400

400

400

Max flap size

560

560

560

560

Min flap size

50

50

50

50

Max height

2000

2000

2000

2000

Min height

150

150

150

150

Max stitching tongue width (mm)

45

45

45

45

Stitching distance (mm)

30-120

30-120

30-120

30-120

Number of stitches

1-99

1-99

1-99

1-99

Stitching speed (stitches/minute)

500

500

500

500

Machine weight (tons)

2.5

3

3.5

5

Power

7 kW

7 kW

7 kW

7 kW

Total: FOB Tianjin Port, China (USD)

Note: (This price does not include installation fees)

1. Quotation date: Validity: 30 days

2. Delivery: 30-50 days after receipt of deposit

3. Payment method: 30% T/T down payment before shipment, 70% T/T

4. Installation and training: Buyer needs to pay for round-trip air tickets, accommodation fees, and USD 100 per engineer per day)

5. Warranty period: 12 monthsFeatures:

Original imported German Siemens/Japanese Mitsubishi dual servo drive, accurate precision, reduced mechanical transmission parts, effectively reducing machine failure rate

Taiwan Weintek touch screen operation, convenient and quick parameter (stitch distance, number of stitches, stitch type, rear baffle) changes

The rear electric baffle is driven by a stepping motor, with accurate dimensions, making size changes more convenient and faster

The entire set of stitching heads uses original Taiwanese parts, extending the service life of the machine head

Can complete single stitch, double stitch, and reinforced stitch (double stitch at both ends, single stitch in the middle) in one go, suitable for different customer requirements for stitch types

One machine with two uses: can stitch single-piece jointed cartons and double-piece jointed cartons

Changing carton size and adjusting carton stitch distance only takes one minute with automatic computer setting, greatly saving time and making operation convenient

The front paper feeding section automatically counts, and the paper feeding table is equipped with a photoelectric sensing device, which automatically rises when feeding paper

The rear section has an automatic counting function, and the number of finished products can be stacked according to the set quantity (2-99) and sent to the end of the conveying machinery, which is convenient for packaging and bundling

Whole machine order-based adjustment, can store 99 orders

Automatic wire feeding system with no-wire alarm, 20KG large flat wire spool, saving time

Machine features: Three-layer, five-layer, and corrugated layer thickness adjustment fully controlled by computer, fast and accurate

Whole machine isolation transformer protection device, better protecting the service life of the whole machine's computer electrical appliances

Main component brands:

Component name

Brand

Machine head servo motor

Japan Yaskawa

Paper feeding servo motor

Japan Yaskawa

PLC

Japan Omron

Contactor, circuit breaker

German Siemens

High-speed stitching head

German Siemens

Intermediate relay

France Schneider

Cylinder, solenoid valve

Taiwan Airtac

Touch screen

Taiwan Weintek

Entire stitching head assembly

Japanese mold steel

Blade bottom die

German alloy steel

Zero return switch

Japan Omron

Photoelectric switch, proximity switch

China Autonics

Geared motor

China

Worm gear reducer

China

Brake motor

China

Bearing

Japan NSK

Product Consulting